Natural rutile is the cleanest and purest form of titanium dioxide, with the other primary form being ilmenite. Natural rutile hosts a titanium dioxide level of roughly 95%, whereas ilmenite requires a great amount of energy and carbon-intensive processes to approach the same level.

Natural rutile is generally considered a superior titanium product due to its high TiO2 content, which results in higher purity and as well as having environmental benefits.

The benefits of natural rutile over ilmenite upgraded into synthetic rutile or titanium slag are:

Higher purity

Purer form and fewer contaminants, making it a preferred feedstock for producing high-quality chloride pigment and titanium metal.

Reduced environmental footprint

Less ore required (reducing freight) and less waste generated (landfill, waste treatment and emissions), alongside lower transformation energy / carbon consumption.

Operational efficiency

Higher chlorinator utilisation and lower chlorine/petcoke consumption.

Pigment (paint, paper, plastics, inks, coatings)

Rutile is primarily used as a pigment. It is sized and processed to create a bright white powder that serves as the primary source of white coloring in everyday products such as paint and toothpaste.

Titanium dioxide minerals are a crucial component in various industrial applications, with approximately 90% of the global production utilised as a pigment in the manufacturing of paint, plastic, paper, and fiber.

Acting as a whitening agent, light reflector, and providing UV and chemical resistance, titanium dioxide minerals offer unparalleled performance and durability in these settings. As a result, they have become an indispensable resource for industries that require high-quality and long-lasting products.

The pigment has a wide range of applications, including house and car paints, laminates, plastic pipes and packaging, inks, clothing, sunscreen, toothpaste, and cosmetics.

Titanium Metal (aircraft frames and engines, medical and sporting goods, industrial applications)

Titanium minerals play a vital role in the production of titanium metal, which boasts the highest strength-to-weight ratio among all commercial metals. Titanium is a chemically resistant metal with high melting point and low conductivity. This exceptional quality makes it an ideal choice in situations where weight is a crucial factor, such as in the aerospace industry. The usage of titanium metal in airplanes helps lessen fuel consumption, which ultimately results in improved efficiency and cost-effectiveness.

It is used in a variety of other applications, including medical implants, defense, sports equipment, and componentry in the offshore mining and petrochemicals industries.

Welding (steel fabrication, ship buildings, pipes, construction, transport)

Rutile plays a pivotal role as an element in welding electrodes, ensuring their ease of use and effectiveness in various industries such as construction, manufacturing, and shipbuilding.

The utilisation of rutile in welding electrodes increases the safety, durability, and strength of steel joining. It remains a crucial component in the manufacture of safe, reliable, and long-lasting welds.

Sierra Rutile is an established global supplier of a range of high-quality products. Our key products include:

Standard Grade Rutile (SGR)

Considered to be an industry leading high quality product and is consumed primarily in the manufacture of titanium dioxide pigment and titanium sponge. Accounts for 85-90% of Sierra Rutile’s annual rutile production.

Industrial Grade Rutile (IGR)

Well suited to high quality flux core wire applications due to its excellent packing density and low contaminant level. Generally trades at a premium to competing rutile products.

High-grade chloride ilmenite

Suitable for direct chlorination into titanium dioxide pigment and transformation into titanium slag.

Zircon In Concentrate (ZIC)

ZIC is a by-product stream typically containing around 20-25% zircon as well as other heavy minerals. The zircon is extracted and consumed in applications such as ceramic tiles, sanitary ware, foundry coatings, refractories, and in the chemical industry.

Demand

Most of the world’s rutile is transformed into TiO2 (white) pigment. In 2023 pigment demand fell below typical GDP trend line growth rates to below historical levels. Slowing demand was driven by: low global housing activity, materially increased interest rates and persistent inflation. By contrast, titanium metal demand has a sustained strong outlook, alongside welding.

Longer term, global growth and limited substitution/recycling of titanium dioxide containing products is anticipated to support demand.

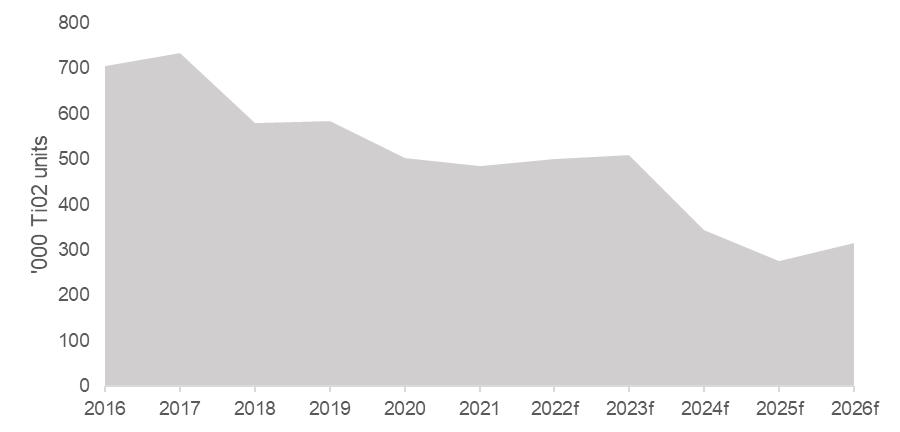

Supply

In response to macroeconomic headwinds, titanium feedstock producers are lowering production. Since there has been limited capital investment in new or replacement supply, Sierra Rutile is well placed to benefit from limited future availability of rutile since the company has a proven track record, established customer base, and given the quality of our natural rutile product.

Sierra Rutile’s operations supply > 20% of global natural rutile. No other large scale rutile mines able to enter production by end 2026.

Future Pricing

Recovering demand expected to outpace constrained rutile supply over the medium term, supporting reinvestment in replacement supply from deposits like Sembehun.

Projected Global Rutile Supply

Source = TZMI/SRL estimates

Source = TZMI/SRL estimates